MASONRY REPAIRS

WHAT ARE MASONRY REPAIRS

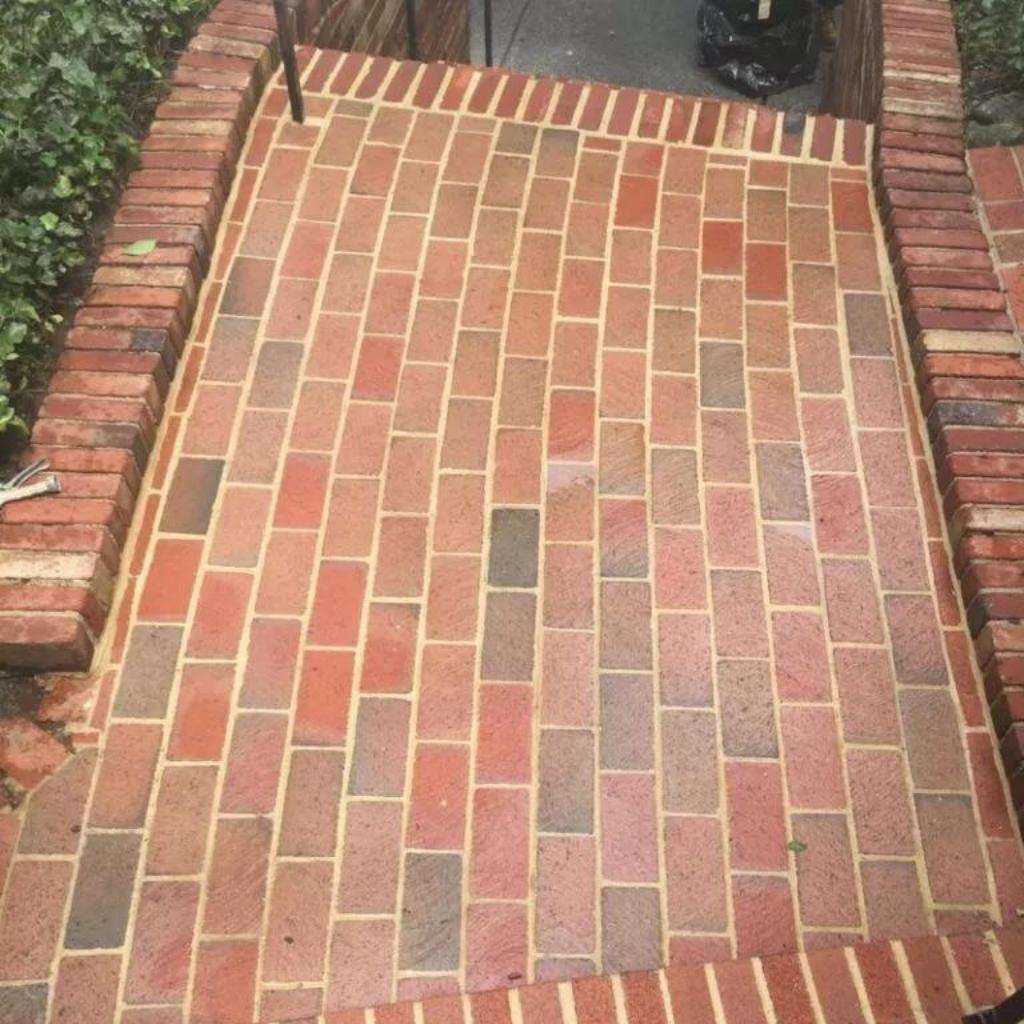

Cracked or chipped bricks, crumbling mortar, or discoloration are all signs that your masonry needs to be repaired (which indicates that the masonry is retaining moisture). If you observe any of these indicators, your masonry will most likely need to be restored.

Patching & Filling Holes and Cracks in the mortar is what masonry repair entails. It also entails removing and repairing old mortar or bricks that have deteriorated structurally.

Masonry repair also involves stone that needs to be repaired. Patching and repairing broken stones, as well as restoring old stones to like-new condition, are all examples of stone repair.

Masonry Rehabilitation frequently necessitates the replacement of stone, brick, and mortar in certain areas. If this is essential, the repair team must first match any new material to the existing material to avoid any visual differences. Normal wear and tear, as well as unintentional damage, can cause masonry to deteriorate over time. Experts in Masonry Repair can assist you in either case.

HOW IS ASPHALT CREATED?

Predose is the initial step in the construction of asphalt pavement. The aggregate components of Asphalt Pavement are weighed using a belt weighing apparatus, depending on the asphalt formula. A belt weigher is used so that the materials can be weighed and transported to the next step in the process at the same time.

The aggregate components are dried in the second step. The components are dried at around 300 Degrees in a rotary drying drum. The aggregate is reweighed after drying because drying might change its weight. The components that have been warmed or dried are now sorted and stored in silos.

After that, the aggregates are moved to the mixer. The binding material, often knows as Liquid Asphalt, is kept in separate heated tanks to keep it liquid and ready to mix. After the aggregate has been put into the mixer, the asphalt is injected at a measured rate of flow. To make the paving material, the aggregate and binder are fully mixed together.

The Hot Asphalt Mix is then stored in a heated silo once it is made. Most asphalt plants have multiple chambers where different recipes can be stored. The asphalt is stored and maintained hot until it is delivered to the project site by dump trucks.

USES OF ASPHALT

Asphalt can be found almost everywhere in Canadian Towns. Asphalt is a semi-solid, sticky type of petroleum that is used to bind aggregate together. Asphalt is a versatile substance that provides a smooth, long-lasting surface for driveways, sidewalks, highways, and parking lots.

Other applications of asphalt are less prevalent, although they are nonetheless significant in construction and outdoor settings. Asphalt is used to waterproof buildings and surfaces, as well as in shingles for residential roofing, in its fluid-like condition. Asphalt has a wide range of industrial and recreational applications, making it an excellent choice for a wide range of construction projects.

NOISE REDUCTION & COST-EFFECTIVE

The “Silent” pavement choice is asphalt pavement. Asphalt absorbs road noise due to its open-graded surfaces, fine-graded surfaces, and materials employed.

When compared to concrete, asphalt is far more Cost-Effective to install. Crude oil is one of the most important components of every asphalt mix. As a result, changes in crude oil prices might influence changes in asphalt prices.

NEED HELP WITH ASPHALT PAVING?

Our Masonry Contractors delivers High-Quality Workmanship in masonry and paving services with guaranteed client satisfaction. We provide a wide range of services for all kinds of needs. Call Us or Enquire today to receive a free estimate.

For Asphalt Paving services on your next project, contact All Season Paving and Masonry.

FREE Consult Form

Thanks for the opportunity! We’ll be in touch within 24 hours!